Paternoster / Walking Beam Furnace

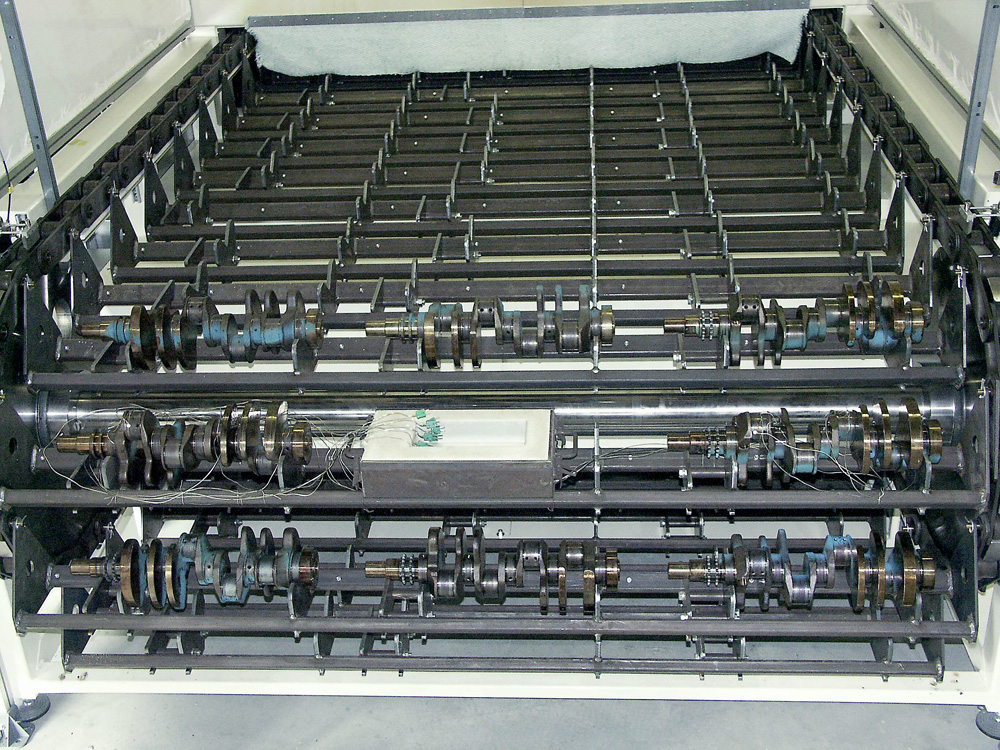

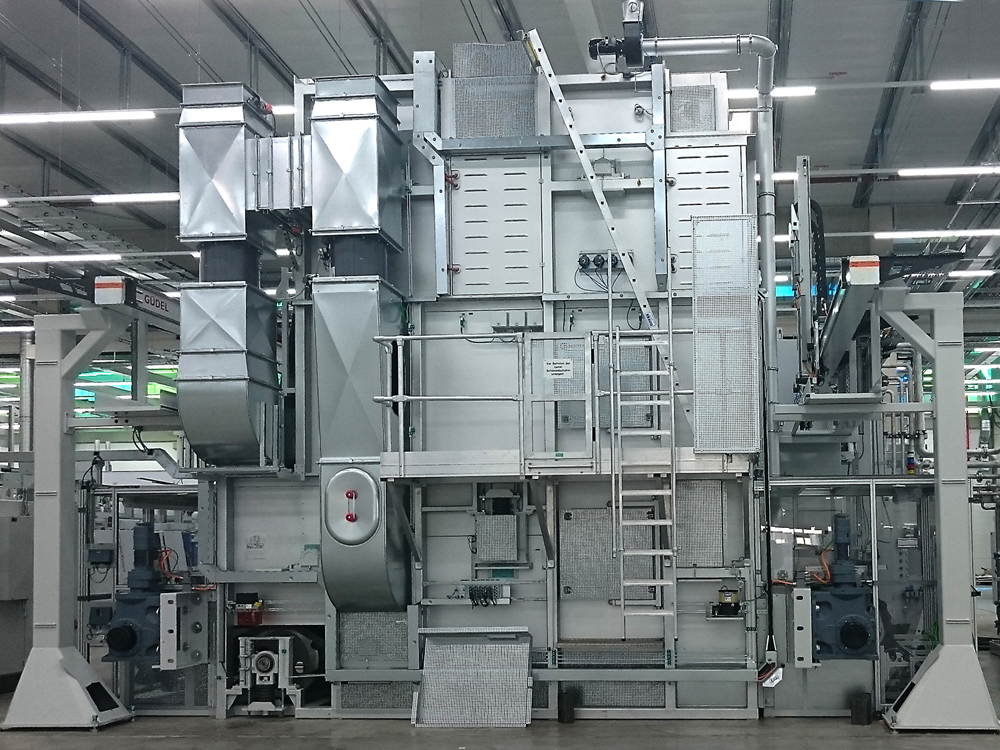

For tempering resp. the temper annealing of crankshafts, camshafts, axles and others after the hardening process, multi-zone chain-conveyor ovens are used (heating-up, holding, cooling).Paternoster design is space-saving and complete height of workshop hall can be used.

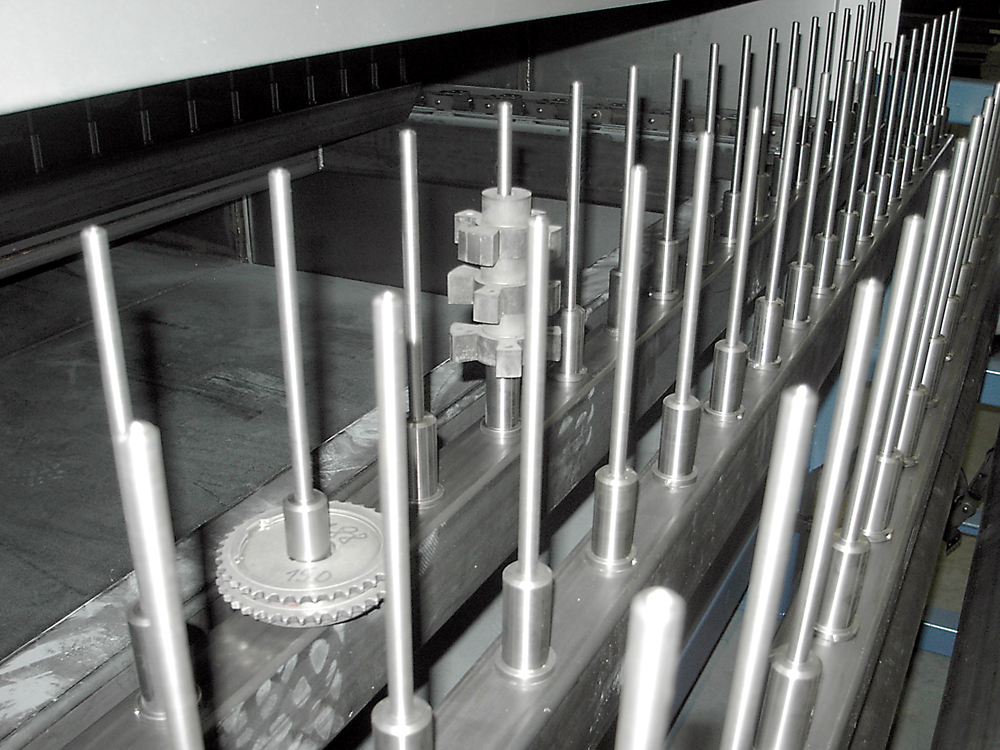

The double-tracked crosshead workholder can be executed multi-lane to pick-up 4 or 5 or more multi-cylinder crankshafts. A special construction is the Walking Beam Oven for cycle-mode-transport, e.g. for ship crankshafts.

Rotary Oven

For ageing / tempering of steering parts/knuckles in different temperature ranges

Paternoster / Walking Beam Furnace

For tempering resp. the temper annealing of crankshafts, camshafts, axles and others after the hardening process, multi-zone chain-conveyor ovens are used (heating-up, holding, cooling). Paternoster design is space-saving and complete height of workshop hall can be used.

Chamber Furnace

Chamber Furnaces are used for small batches and small capacities, as well as for special applicationsContinuous Furnace / Belt Furnace

For stress relief of material structure of metallic workpieces conveyor belt ovens are used, which can be electric or gas heated, and which are equipped with air circulation fans. Range of temperature is between 200° and 750°C. Subsequent down cooling is effected in an air cooling section or indirect water cooling section.